Author: Sona Dadhania, Senior Technology Analyst at IDTechEx

Even with a new, more “industry-friendly” administration in the White House, regulator debate on “forever chemicals”, or PFAS, continues to evolve across the United States. For example, the state of New Mexico recently passed a ban on intentionally added PFAS (per- and poly-fluoroalkyl substances) in consumer products, with some notable exemptions. State legislators in North Carolina have proposed a bill to ban non-essential PFAS uses and prevent PFAS contamination in drinking water. The new administrator for the Trump Administration's Environmental Protection Agency (EPA), Lee Zeldin, has previously expressed support for federal action on PFAS contamination.

However, there are other actions by the US EPA and Republican members of Congress that suggest a plan to loosen federal regulations on PFAS. For example, two House Republican lawmakers proposed a bill to repeal a 2024 regulation that closed the “low volume exemption” loophole for PFAS, which had allowed PFAS produced in small enough quantities to be sold in the US without review from federal regulators.

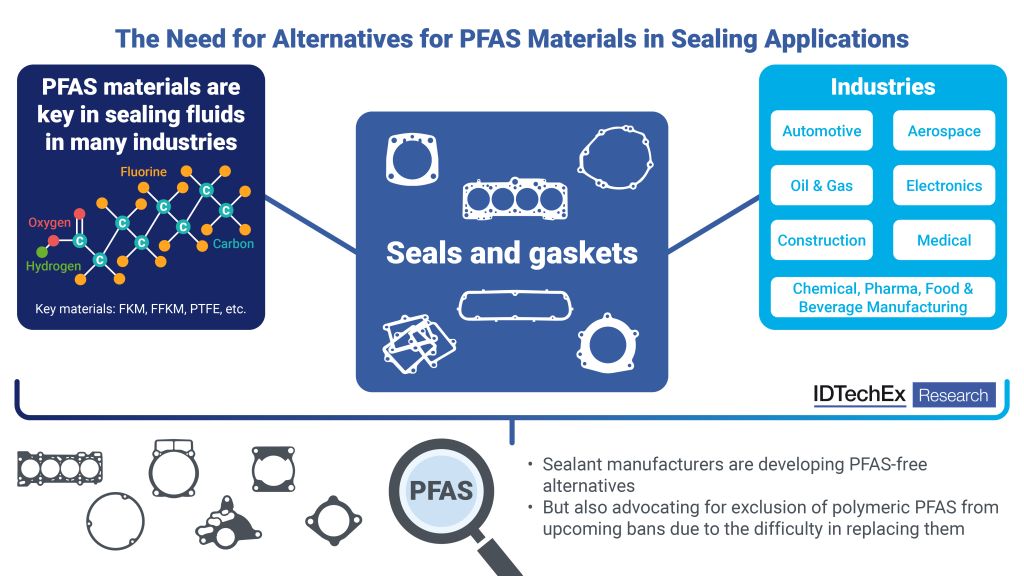

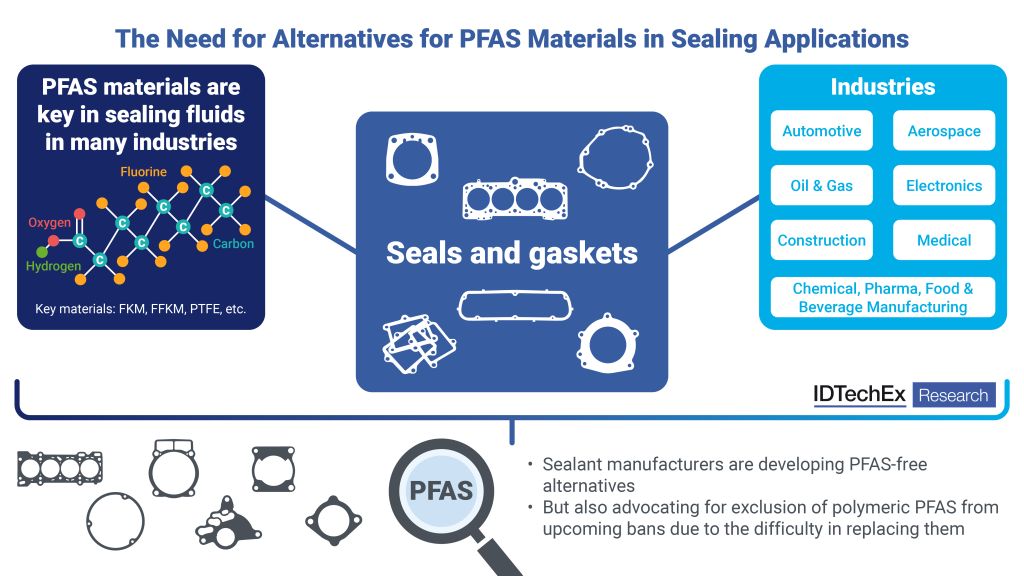

As such, the overall picture of PFAS regulations in the US, as well as other jurisdictions around the world, is rather murky. With such uncertainty, it will be essential for every industry to investigate their options if PFAS regulations eventually end up targeting them. One key area that extensively utilizes PFAS-based materials is sealing applications. In IDTechEx's report, “Per- and Polyfluoroalkyl Substances (PFAS) 2025: Emerging Applications, Alternatives, Regulations“, the challenges faced by the sealing industry, which uses PFAS-based materials in numerous sectors, and potential alternatives for PFAS in these sectors are discussed.

The need to examine alternatives for PFAS materials in sealing applications. Source: IDTechEx

Introducing seals and gaskets

A gasket, seal, or O-ring is a mechanical component that creates a barrier between two surfaces to prevent leakage of fluids. These components must maintain their sealing function while withstanding challenging conditions like high temperatures, aggressive chemicals, mechanical stress, and wear, particularly in dynamic applications with moving parts. Their reliability is crucial since failure can lead to chemical leakage, equipment breakdown, hazardous situations, or costly maintenance. For example, a failed engine seal could lead to lubricant loss and complete engine failure, while a broken gasket in a chemical plant could result in dangerous chemical leaks.

Industries that require sealing include:

- Automotive

- Aerospace

- Medical

- Oil & Gas

- Electronics

- Hydrogen

- Manufacturing of chemicals, pharmaceuticals, food & beverage, etc.

What PFAS materials are used in sealing applications?

While numerous types of rubbers and silicones are utilized in sealing applications, materials that are categorized as polymeric PFAS are often highly desired for demanding sealing applications due to their:

- High chemical and corrosion resistance

- High heat resistance

- Low friction co-efficient

- Low uptake of gases and low permeation co-efficient

- And low degree of swelling (among other desirable material properties)

These highly desired polymeric PFAS include fluoropolymers like PTFE and ETFE, fluoroelastomers like FKM and FEPM, and perfluoroelastomers like FFKM. It should be noted that the fluoropolymer industry opposes its categorization under the PFAS umbrella. Industry has also lobbied for exemptions for fluoropolymers in PFAS regulations, successfully in some cases; for example, the recent ban on PFAS in consumer products in New Mexico excludes fluoropolymers.

Alternatives for PFAS in sealing applications

Nonetheless, these materials are still being targeted by current regulations and may be limited by future regulations. This puts the onus on the sealing industry to investigate applications where non-PFAS materials can also perform well. This is a challenge that numerous materials suppliers and sealing solution providers have already started to tackle. Materials already used in sealing applications, like metal, EPDM rubber, silicone rubbers, etc. are being re-evaluated to see where they can effectively replace PFAS materials. Other less common materials, such as graphite and polyphenylene sulfide, are being investigated for emerging sectors, like sealing applications in the hydrogen value chain. Trends towards liquid sealants in areas like electric vehicle battery packs also support adopting non-PFAS sealing materials.

Still, many representatives of industry, like the European Sealing Association, argue that incumbent PFAS materials will be very difficult to replace in certain applications depending on that application's requirements (i.e. need for chemical resistance, off gassing concerns, etc.). As a result, the sealing industry is arguing for broader exemptions for fluoropolymers and fluoroelastomers in such applications, alongside the fluoropolymer manufacturing industry. It remains to be seen how PFAS regulations will develop and how many sealing applications might need to switch to non-PFAS materials; this will be an area that IDTechEx will continue to monitor.

PFAS alternatives in emerging applications

To understand more about the alternatives for PFAS materials, challenges, regulations, and outlook for PFAS in sealing for emerging high-tech industries, refer to IDTechEx's leading report, www.IDTechEx.com/PFAS. Downloadable sample pages are also available.

For deeper insights into PFAS regulations, alternatives, and treatment technologies, access IDTechEx's comprehensive research at www.IDTechEx.com/Research/Sustainability.