- Prestigious project win during the pandemic

- Nuberg EPC has delivered more than five Sulphuric Acid projects worldwide

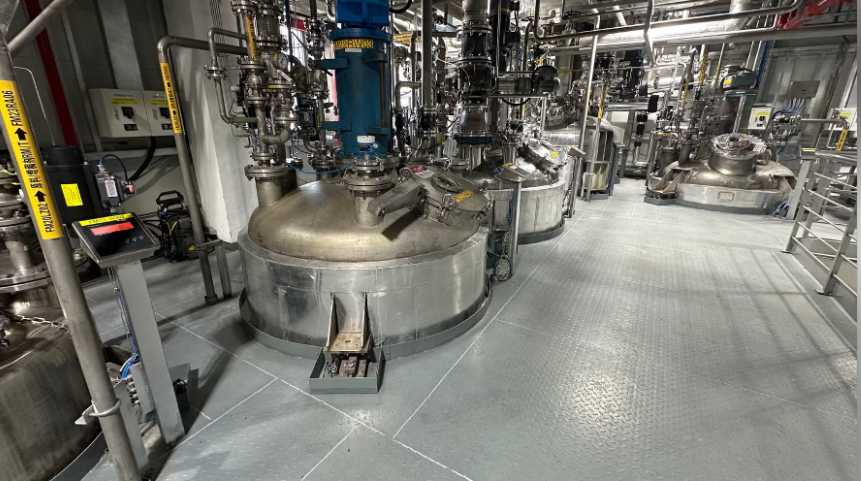

- The Sulphuric Acid plant will be based on advanced DCDA Technology.

A global EPC and turnkey project management company, Nuberg EPC has been awarded the prestigious 500 MTPD Sulphuric Acid Plant project on EPC & LSTK basis in Egypt. The project, which was awarded during the pandemic, is owned by Sprea Misr, a leading chemicals and plastics manufacturer in Ramadan City, Egypt. Nuberg EPC will be the single-point solution company responsible from concept to commissioning of the project.

The 500 TPD Sulphuric Acid Plant project will be based on the latest Double Contact Double Absorption (DCDA) process technology. The Double contact process is used for the production of sulphuric acid in high concentrations that is required for industrial purposes. The project also incorporates a 5MW turbine with a steam-based power generation plant with a complete bypass arrangement. This is the first time that Nuberg EPC is building a turbine unit for electricity production. Sulphuric Acid produced in the plants will be provided to the agriculture industry for the production of urea and other fertilizers.

This project comes as another milestone for Nuberg EPC in Egypt, as it is the fourth turnkey project for the company. Nuberg has also completed three other turnkey projects in Egypt namely, a Caustic Soda plant for the Egyptian Petrochemical Company in Alexandria, a Calcium Chloride plant for TCI Sanmar Chemicals in Port Said, and a Sulphuric Acid plant for AGROCHEM in Alexandria.

Signing the contract amidst the pandemic is yet another achievement for Nuberg EPC. In the Middle East, Nuberg EPC has successfully delivered over fifteen turnkey projects in countries like Oman Qatar, Saudi Arabia, Turkey, and the UAE. This has positioned Nuberg EPC as one of the top EPC companies in the region.

On being awarded the project, Mr A. K. Tyagi, MD, Nuberg Engineering commented, “We are thankful to Sprea Misr for entrusting our turnkey project engineering capabilities and our EPC services and solutions with its Sulphuric Acid plant. We are excited to partner with them and strengthen our relationship even further. Armed with competent, qualified, and professional engineers along with advancements in sulphuric acid plant technology, we are committed to commission the project by the first quarter of 2022; faster than the industry average of 16 months.”

He further stated, “Nuberg EPCs scope of services for this project includes Process Design & Technology including Product and Technology Development, Process Know-how & Licensing, Basic Engineering, Front End Engineering Design (FEED), Construction Management, Operation & Maintenance, Detailed Engineering, Project Management, Commissioning, EPC & LSTK Solutions, Heavy Fabrication, and start-up of the plant.”

Sulphuric Acid finds its way through a wide range of applications in the hydrocarbon (oil & gas) industry and is one of the most important industrial chemicals. The major use of sulphuric acid is in the production of fertilizers, in petroleum refining to wash impurities out of gasoline, in derivatives, and other refinery & petrochemical products, in processing metals, and in automobiles as the electrolyte in the lead-acid storage battery.

Nuberg EPC has been providing plant design, engineering, technology, and turnkey solutions to the sulphuric acid industry for 25 years. Nuberg EPC has its own technology specially designed and developed to increase the efficiency and cost-effectiveness of Sulphuric Acid plants. The company is a global leader for not only executing turnkey Chemical and Fertilizer projects worldwide but also serves Hydrocarbon, Steel, and Nuclear & Defence industries globally.